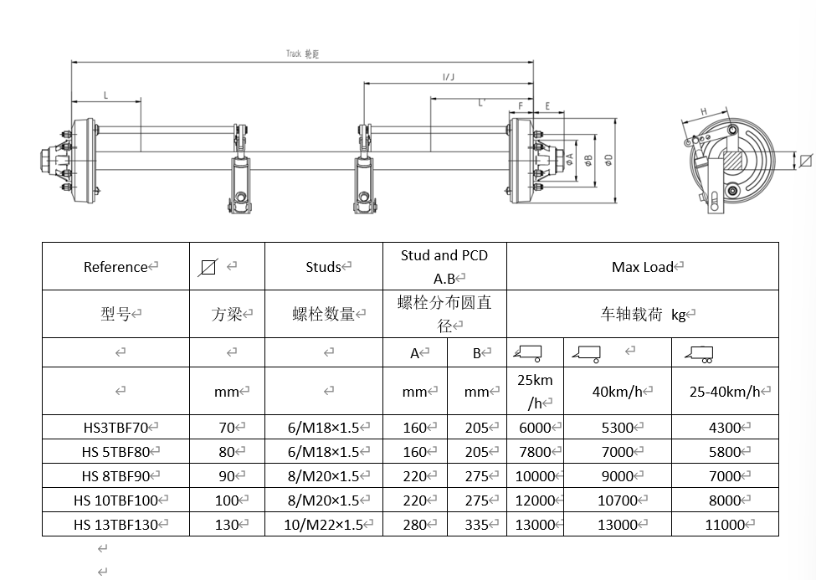

Whole axle brake bearings

Bearings play a crucial and irreplaceable role in mechanical design, covering a wide range. It can be understood that without bearings, the shaft is a simple iron rod. Below is a basic introduction to the working principle of bearings. Rolling bearings, developed based on bearings, work on the principle of using rolling friction instead of sliding friction. They are generally mechanical basic components with strong universality, standardization, and serialization, composed of two rings, a set of rolling elements, and a cage. Due to the different working conditions of various machinery, different requirements are put forward for rolling bearings in terms of load capacity, structure, and performance. For this reason, rolling bearings need to have various structures. However, the most basic structure is composed of an inner ring, an outer ring, a rolling element, and a retainer - commonly referred to as the four major components.

The main function of bearings is to support the mechanical rotating body, in order to reduce the mechanical load friction coefficient of the equipment during the transmission process. Bearings are components that fix and reduce the load friction coefficient during mechanical transmission. It can also be said that when other components generate relative motion on the shaft, they are used to reduce the friction coefficient during power transmission and maintain a fixed center position of the shaft.

The early form of linear motion bearings was to place a row of wooden rods under a row of pry plates. Modern linear motion bearings use the same working principle, but sometimes use balls instead of rollers. The simplest type of rotary bearing is a sleeve bearing, which is simply a liner sandwiched between the wheel and axle.

This design was later replaced by rolling bearings, which used many cylindrical rollers to replace the original lining, with each rolling element acting like a separate wheel. Due to differences in manufacturing accuracy and material uniformity, even bearings of the same material and size in the same batch, when used under the same working conditions, have different lifespans.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible