Product DescriptionThis machine is a disc lawn mower that can be used to harvest grass such as alfalfa, ryegrass, oat grass, and so on. It has high efficiency and is more suitable for cutting higher crops. The blade and spiral handle stall, making it easy to move up and down. It is suspended by two springs and can adapt to uneven ground conditions without damaging the grass. This machine also has a safe installation. During operation, the lawn mower can move backwards when encountering obstacles, which can protect the machine.advantage:1.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area. The structure of this machine is compact and the operation is easy and reliable and the residues is lower after cutting.Modelunit 9G-1.49G-1.69G-1.89G-2.1Working widthmm1400160018002100Working depthmm50-80PTO Rotation speedr/min540PTO shaft spline6 splineTotal weightkg120124128135Matched powerhp12-2015-2020-3020-30LinkageThree-point suspension I type

Contact Now

Model9GDM-1.259GDM-1.359GDM-1.65Tractor power required (HP)25-4035-5045-60Cutting width (m)1.251.351.65Quantity of drum disc222Work efficiency (km/h)151515Quantity of blades 666Cutting blade size (mm)47*100*347*100*347*100*3Cutting blade material 65Mn65Mn65MnPTO rotation speed (r/min)540540540Drum rotation speed (r/min)162016201620Overall dimension (mm)2300*800*10502400*850*10503000*900*1100Weight(Kg)330350448

Contact Now

Model9GDM-1.259GDM-1.359GDM-1.65Tractor power required (HP)25-4035-5045-60Cutting width (m)1.251.351.65Quantity of drum disc222Work efficiency (km/h)151515Quantity of blades 666Cutting blade size (mm)47*100*347*100*347*100*3Cutting blade material 65Mn65Mn65MnPTO rotation speed (r/min)540540540Drum rotation speed (r/min)162016201620Overall dimension (mm)2300*800*10502400*850*10503000*900*1100Weight(Kg)330350448

Contact Now

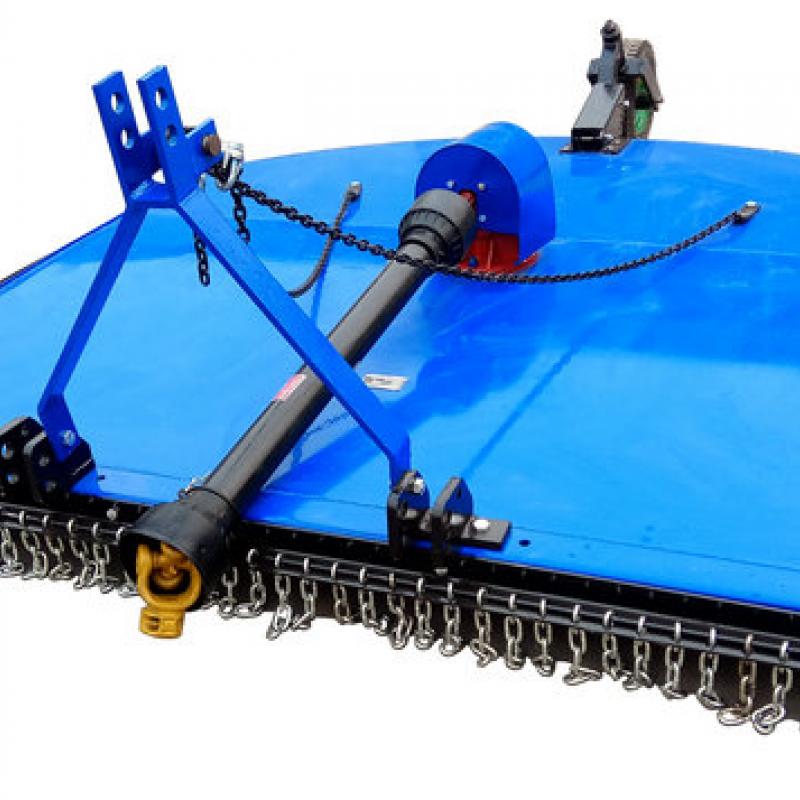

this rear mounted rotary mower is added the chain in the front and rear of the tractor rotary slasher to protect the worker. Driven by the 3 gear boxes to keep widely working width.

Contact Now

Model9GDM-1.259GDM-1.359GDM-1.65Tractor power required (HP)25-4035-5045-60Cutting width (m)1.251.351.65Quantity of drum disc222Work efficiency (km/h)151515Quantity of blades 666Cutting blade size (mm)47*100*347*100*347*100*3Cutting blade material 65Mn65Mn65MnPTO rotation speed (r/min)540540540Drum rotation speed (r/min)162016201620Overall dimension (mm)2300*800*10502400*850*10503000*900*1100Weight(Kg)330350448

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area. The structure of this machine is compact and the operation is easy and reliable and the residues is lower after cutting.Modelunit9G-1.49G-1.69G-1.89G-2.1Working widthmm1400160018002100Working depthmm50-80PTO Rotation speedr/min540PTO shaft spline6 splineTotal weightkg120124128135Matched powerhp12-2015-2020-3020-30LinkageThree-point suspension I type

Contact Now

----Products Show---- ----Package & delivery---- ----FAQ----Q1: Are you a factory or trading company?We are a factory with self-supported import and export right. Q2: How can I trust on your company?We are a fully registered manufacture and exporting company by China Export Registration Authorities. Moreover, our products have been exporting to a number of countries including Switzerland, Russia, Spain, Netherlands, Australia, Peru, Thailand, Pakistan, Indonesia, Tanzania, Nigeria, South Africa, Sudan, Congo etc.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area.

Contact Now

this rear mounted rotary mower is added the chain in the front and rear of the tractor rotary slasher to protect the worker. Driven by the 3 gear boxes to keep widely working width.

Contact Now

Product Description This machine is disc mower, can be used to harvest the pasture, herbage, such as alfalfa, ryegrass, oat grass and so on., with high efficiency, are more suitable for cutting more taller crop. The cutter arbor stalled with the spiral hand shank, easily to go up and down, use two springs to hang, can adapt to the situation of the ground which is concave-convex, and doesn’t destroy the grass ground. The machine also with safe installations, when working, the mowing plate can moving back when meet the barrier, can protect the machine Advantages:1.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area. The structure of this machine is compact and the operation is easy and reliable and the residues is lower after cutting.Modelunit9G-1.49G-1.69G-1.89G-2.1Working widthmm1400160018002100Working depthmm50-80PTO Rotation speedr/min540PTO shaft spline6 splineTotal weightkg120124128135Matched powerhp12-2015-2020-3020-30LinkageThree-point suspension I type

Contact Now

this rear mounted rotary mower is the updated version from the type 9GX series.we add the chain in the front and rear of the tractor rotary slasher to protect the worker.

Contact Now

this rear mounted rotary mower is the updated version from the type 9GX series.we add the chain in the front and rear of the tractor rotary slasher to protect the worker.

Contact Now

Model9GDM-1.259GDM-1.359GDM-1.65Tractor power required (HP)25-4035-5045-60Cutting width (m)1.251.351.65Quantity of drum disc222Work efficiency (km/h)151515Quantity of blades 666Cutting blade size (mm)47*100*347*100*347*100*3Cutting blade material 65Mn65Mn65MnPTO rotation speed (r/min)540540540Drum rotation speed (r/min)162016201620Overall dimension (mm)2300*800*10502400*850*10503000*900*1100Weight(Kg)330350448

Contact Now

this rear mounted rotary mower is added the chain in the front and rear of the tractor rotary slasher to protect the worker. Driven by the 3 gear boxes to keep widely working width.

Contact Now

this rear mounted rotary mower is added the chain in the front and rear of the tractor rotary slasher to protect the worker. Driven by the 3 gear boxes to keep widely working width.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area. The structure of this machine is compact and the operation is easy and reliable and the residues is lower after cutting.Modelunit9G-1.49G-1.69G-1.89G-2.1Working widthmm1400160018002100Working depthmm50-80PTO Rotation speedr/min540PTO shaft spline6 splineTotal weightkg120124128135Matched powerhp12-2015-2020-3020-30LinkageThree-point suspension I type

Contact Now

this rear mounted rotary mower is added the chain in the front and rear of the tractor rotary slasher to protect the worker. Driven by the 3 gear boxes to keep widely working width.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area. The structure of this machine is compact and the operation is easy and reliable and the residues is lower after cutting. Modelunit9G-1.49G-1.69G-1.89G-2.1Working widthmm1400160018002100Working depthmm50-80PTO Rotation speedr/min540PTO shaft spline6 splineTotal weightkg120124128135Matched powerhp12-2015-2020-3020-30LinkageThree-point suspension I type

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area. The structure of this machine is compact and the operation is easy and reliable and the residues is lower after cutting. Modelunit9G-1.49G-1.69G-1.89G-2.1Working widthmm1400160018002100Working depthmm50-80PTO Rotation speedr/min540PTO shaft spline6 splineTotal weightkg120124128135Matched powerhp12-2015-2020-3020-30LinkageThree-point suspension I type

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area.

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area.

Contact Now