Install bridge bearings on the half shaft to attenuate vibration and protect the half shaft and other components.The half shaft (drive shaft) is subjected to alternating stresses such as torsion, shear, tension and compression, and impact, which can also cause torsional and bending vibrations of the drive shaft, resulting in additional stresses; Uneven stress distribution; There is sliding friction between the drive shaft neck and the bearing.The shaft that transfers torque between the half shaft gearbox reducer and the drive wheel (previously mostly solid, but due to the easier control of une

Contact Now

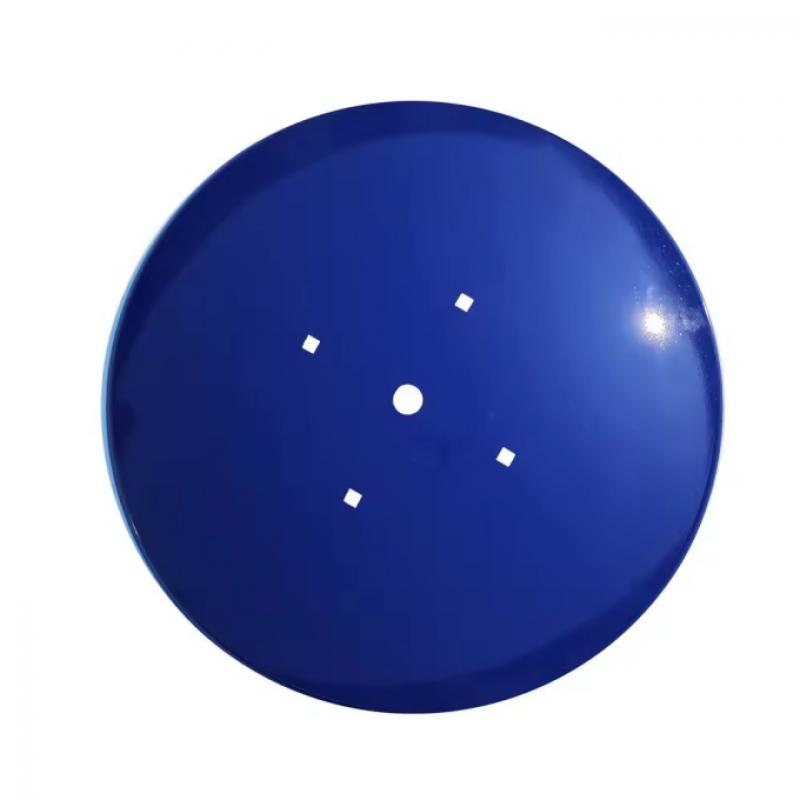

Product descriptions from the supplierOverview Agricultural machine parts disc harrow bearing house brazil bearing assembly Product DescriptionDuo-Cone mechanical seals.Taper roller bearings to absorb load in two ways - axial & radial.Low maintenance.Long life span.Total length 178-248mm, Weight 12-24kg

Contact Now

Agricultural Disc Harrow Oil bathed bearing assembly PRODUCT OVERVIEW

Contact Now

Product descriptions from the supplier:PRODUCT DESCRIPTION:The half shaft is used to transfer power between the differential and the drive wheels. The half shaft of a regular non disconnecting drive axle can be divided into three types: fully floating, 3/4 floating, and semi floating depending on the external support form.Expand the information on car drive shafts and design a transmission device for driving wheels located at the end of the car's transmission system. Its function is to transmit torque from the differential half shaft gear to the driving wheels.

Contact Now

The half shaft is used to transfer power between the differential and the drive wheels. The half shaft of a regular non disconnecting drive axle can be divided into three types: fully floating, 3/4 floating, and semi floating depending on the external support form.Expand the information on car drive shafts and design a transmission device for driving wheels located at the end of the car's transmission system. Its function is to transmit torque from the differential half shaft gear to the driving wheels.

Contact Now

1.In general, the efficiency of using axle bearings is similar to that of power and lubrication bearings, but the rocker arm hybrid lubrication bearings are much higher.2. The radial clearance of the axle bearing is relatively small, and the radial angular contact bearing can be pre tightened with pre tightening force to eliminate the clearance, resulting in high performance during operation.Compared to bearings of the same type, axle bearings have a smaller width and a compact structure.4.

Contact Now

1.In general, the efficiency of using axle bearings is similar to that of power and lubrication bearings, but the rocker arm hybrid lubrication bearings are much higher.2. The radial clearance of the axle bearing is relatively small, and the radial angular contact bearing can be pre tightened with pre tightening force to eliminate the clearance, resulting in high performance during operation.Compared to bearings of the same type, axle bearings have a smaller width and a compact structure.4.

Contact Now

1.In general, the efficiency of using axle bearings is similar to that of power and lubrication bearings, but the rocker arm hybrid lubrication bearings are much higher.2. The radial clearance of the axle bearing is relatively small, and the radial angular contact bearing can be pre tightened with pre tightening force to eliminate the clearance, resulting in high performance during operation.Compared to bearings of the same type, axle bearings have a smaller width and a compact structure.4.

Contact Now

The half shaft is used to transfer power between the differential and the drive wheels. The half shaft of a regular non disconnecting drive axle can be divided into three types: fully floating, 3/4 floating, and semi floating depending on the external support form.Expand the information on car drive shafts and design a transmission device for driving wheels located at the end of the car's transmission system. Its function is to transmit torque from the differential half shaft gear to the driving wheels.

Contact Now

ItemHSTAY6075Working width7500mmWorking depth250-300mmNo. of discs60 pcsDisc dimension660*6mmBearing Bearing assembly type, 中孔43, 圆轴42Total weight6100kgMatched tractor power240hpLinkage Trailed

Contact Now

Disc harrow is mainly applicable to clean the crop residue before tillage, break the hardened soil and return the chopped straw to the soil, and also can crash the soil after tillage and level the land.It can be used as tillage machine instead of plow on the cultivated land. With the efficient productivity, reasonable utilization of the power, great ability of cutting and shattering the soil , the soil surface is smooth and loosening after harrowing, it is well suitable for heavy clay soil, waste land and weedy field as well.

Contact Now

PRODUCT DESCRIPTION Yucheng Hengshing Machinery Co.,Ltd, professionaly manufacture agricultural implements and spare parts including disc blades, harrow bearing assembly, harrow shaft, plough hubs etc. which are exported to more than 70 countries of America, Thailand, Bolivia, Chile, Peru, Australia, South Africa, Tanzania, Nigeria, Ghana, Sudan, Botswana, Zambia, Zimbabwe etc.

Contact Now

Strongest harrow machine heavy duty offset disc harrow pull type disc harrow Product DescriptionThis LCBB heavy duty offset disc harrow is designed according to the Europe standard.It adopts the features on hydraulic offset modular structure, built-bearing composite design, reasonable structure, bearing seal, long life, durable, easy to transport, easy to adjust, easy maintenance .This heavy duty offset disc harrow also can be used to clean the stubble before tillage , break the hardened and impervious soil surface, crush and spread straw into the field, shatter soil aft

Contact Now

Product descriptions from the supplierOverview Disc Harrow Spare Parts Disc Blade Boron Disc 26inch 28inch Notched Harrow blade PRODUCT DESCRIPTION Yucheng Hengshing Machinery Co.,Ltd, professionaly manufacture agricultural implements and spare parts including disc blades, harrow bearing assembly, harrow shaft, plough hubs etc.

Contact Now

LCBB series of heavy duty disc harrow was designed according to the Europe standard .It adopts the features on hydraulic offset modular structure,built-bearing composite design,reasonable structure, bearing seal, long life, durable, easy to transport, easy to adjust, easy maintenance.This heavy duty harrow also can be used to clean the stubble before tillage,break the hardened and impervious soil surface,crush and spread straw into the field, shatter soil after tillage, and level the land and preserve soil moisture.

Contact Now

1LYA Series paddy field disc plough is designed according to the feature of soil with moisture and more weeds in Southeast Asia ,especially suitable for cultivation in the land with more weeds and bricks.ModelUnit1LYA-6-221LYA-7-22Working widthmm1200-13001300-1400Working depthmm150-200Q’ty of disc67Total weightkg420500Matched powerhp50-7070-90LinkageThree-point suspension II type

Contact Now

3Z series of disc ridger is suitable for ridging after the tillage in the farm field. it consists of heavy duty tubular box frame, 3 point hitch system and discs.the disc blades are made after the heat treatment in the material of 65 Mn spring steel that has better hardness.

Contact Now

This rear mounted rotary mower is the updated version from the type 9GX series.we add the chain in the front and rear of the tractor rotary slasher to protect the worker.

Contact Now

this rear mounted rotary mower is added the chain in the front and rear of the tractor rotary slasher to protect the worker. Driven by the 3 gear boxes to keep widely working width.

Contact Now

Disc harrow is mainly applicable to clean the crop residue before tillage, break the hardened soil and return the chopped straw to the soil, and also can crash the soil after tillage and level the land.It can be used as tillage machine instead of plow on the cultivated land.

Contact Now

Model9GDM-1.259GDM-1.359GDM-1.65Tractor power required (HP)25-4035-5045-60Cutting width (m)1.251.351.65Quantity of drum disc222Work efficiency (km/h)151515Quantity of blades 666Cutting blade size (mm)47*100*347*100*347*100*3Cutting blade material 65Mn65Mn65MnPTO rotation speed (r/min)540540540Drum rotation speed (r/min)162016201620Overall dimension (mm)2300*800*10502400*850*10503000*900*1100Weight(Kg)330350448

Contact Now

Model 9G series of sickle bar mower takes advantage of the offset crank link mechanism to drive the cutter blade mow grass, and it is adequate for cutting the natural and planted grasses in ranch, mountain and hilly area.

Contact Now

Product DescriptionThis machine is a disc lawn mower that can be used to harvest grass such as alfalfa, ryegrass, oat grass, and so on. It has high efficiency and is more suitable for cutting higher crops. The blade and spiral handle stall, making it easy to move up and down. It is suspended by two springs and can adapt to uneven ground conditions without damaging the grass. This machine also has a safe installation. During operation, the lawn mower can move backwards when encountering obstacles, which can protect the machine.advantage:1.

Contact Now